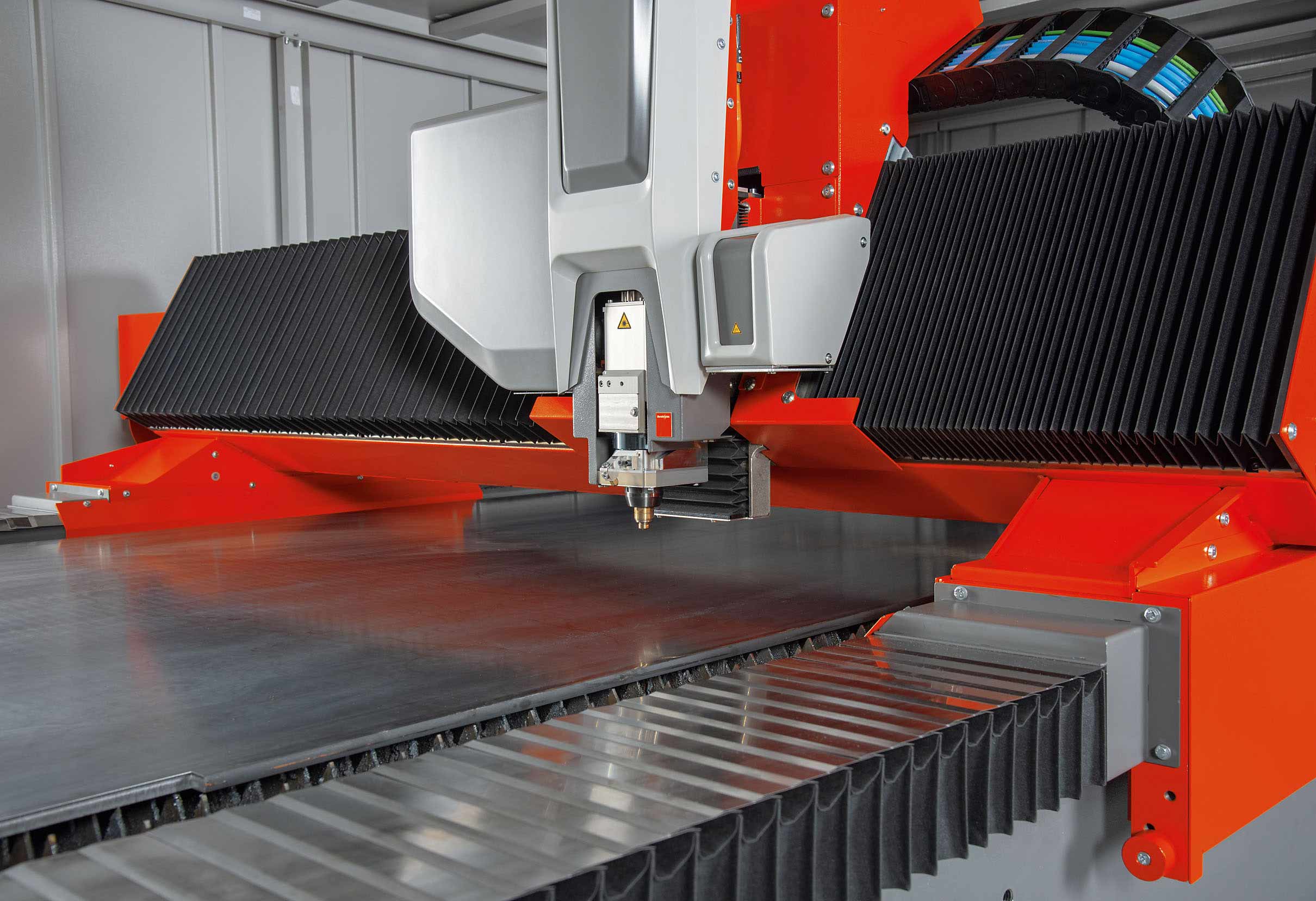

A North Yorkshire engineering company that manufactures more than 80 per cent of the winter maintenance and repair vehicles used on Britain’s roads has ploughed £850,000 into a new state-of-the-art laser cutter.

The new machine purchased by Econ Engineering will not only significantly increase throughput in its engineering workshop, it will also reduce the firm’s carbon footprint.

The £850,000 Bystar Fibre 6225 Dynamic – which will replace its existing Bystar L 4025 – uses nitrogen in the cutting process as opposed to oxygen, which will increase cutting speeds by up to 600 per cent on metal with a thickness of upto 3mm and 400 per cent on materials 4mm to 10mm.

Cutting with nitrogen rather than oxygen eliminates the carbon edge on cut mild steel profiles, this in turn gives improved weldability and provides a cleaner surface for paint adherence and therefore increasing the durability of the painted product. Unfortunately, the salt or brine used for de-icing our roads in cold weather, is highly corrosive for the vehicles used to apply them. Econ has worked closely with their paint suppliers to create specialist paints that protect their vehicles, but the elimination of the carbon edge is another small step to improving their longevity.

And, with the new machine using only 50kw/hr of electricity against 98kw/hr, this will save approximately 75 tonnes of carbon dioxide from entering the atmosphere.

Colin Trewhitt, Econ Engineering’s Factory Manager, said:

The purchase of this new laser cutting machine represents a significant investment for Econ, but one that will bring significant benefits.

On average, we laser cut some 9,000 components every week, ranging in size from 100x50mm to 5500x1800mm, in aluminium/stainless steel and mild steel, and between 25 and 30 tonnes of steel plate.

The new machine will not only allow us to cut faster but will also use a fraction of the power, which was a key consideration for us.

This new technology can individually etch each component with an identification number – even on stainless steel – which will help us to meet the ISO 9001:2015 for parts identification. We expect this to increase our productivity both in the factory and within our service division, as it removes ambiguity around part identification.

Additionally, we are now exploring the viability of creating our own on-site nitrogen generation plant compared to our current method of buying in bulk.

The family run firm, which was set up in 1969, is the country’s largest producer of winter maintenance vehicles. It also has a hire fleet of more than 800 vehicles.

[…] ECON ploughs £850000 into new state-of-the-art laser cutter Harrogate Informer […]